ODVA is committed to ensuring that EtherNet/IP meets all requirements of Industry 4.0 and IIoT. EtherNet/IP is a proven industrial automation network that is object-oriented, multi-vendor interoperable, and highly standardized. EtherNet/IP also leverages TCP/IP and commercial-off-the-shelf hardware and works across HTTP, FTP, SNMP, and DHCP to better connect the work cell to the broader infrastructure. The object-oriented foundation of EtherNet/IP has been a key factor in its current global industrial success and will play an important role in continuing its growth with accelerating IT and OT convergence. Continuous enhancements to EtherNet/IP are both planned and underway to meet future industrial communication and control needs across both the discrete and process industries.

Unparalleled device level security along with best-in-class safety, motion/synchronization, and energy performance within industrial control, combined with inherent TCP/IP capability for higher level communication, make EtherNet/IP an ideal solution for both today and tomorrow. EtherNet/IP was designed to excel at the most challenging control applications while at the same time being future proofed by being based on standard, unmodified Ethernet with the ability to transport critical diagnostic and prognostic information where it needs to go for analysis and action.

Factory floor to cloud connectivity is a key component of IIoT. ODVA is developing an OPC UA Companion Specification for CIP as one way to help address this need. Learn more about OPC UA.

EtherNet/IP In-Cabinet Resource-Constrained Device Solution

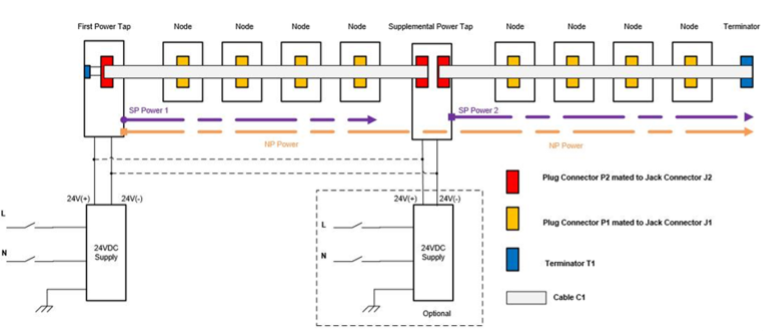

EtherNet/IP in-cabinet resource-constrained device support is a significant technological advancement that utilizes Single Pair Ethernet (IEEE Std 802.3cg-2019 10BASE-T1S) to bring Ethernet to low-level in-cabinet devices such as contactors and push buttons. Limitations including cost, available space, and power consumption have resulted in many edge devices remaining hardwired. However, a lack of network connectivity results in time consuming installation, challenging troubleshooting, and a deficiency of diagnostic information. The steady decline in the cost and size of semiconductor chips combined with the availability of Single Pair Ethernet has enabled an EtherNet/IP in cabinet bus solution that uses a multidrop network and control power cable that spans a single cabinet with one interface per device and one switch port across multiple devices to reduce both commissioning and hardware cost.

EtherNet/IP In-Cabinet Resource-Constrained Multidrop Flat Cable Illustration

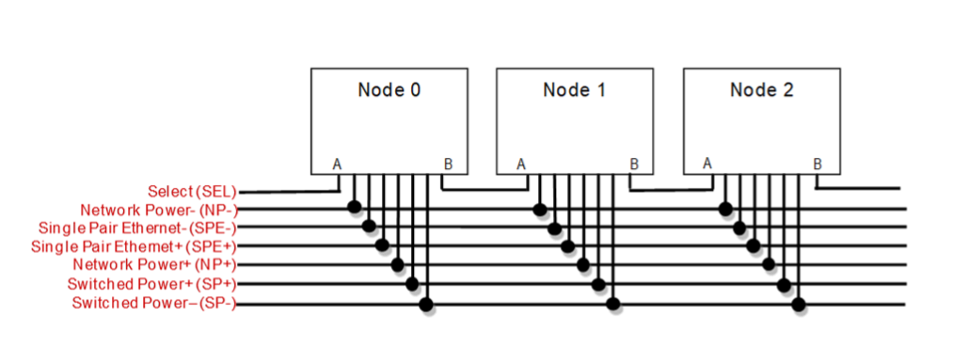

The inclusion of resource-constrained devices within cabinets on an EtherNet/IP network is made possible by low overhead UDP-only communication, a LLDP node topology discovery mechanism, auto-commissioning support, and auto-device replacement support. A new select line circuit facilitates the efficient delivery of system wide sequential commands, eliminates configuration switches by enabling topology discovery based on relative position, and allows for direct connection with programming tools during assembly for parameterization.

Select Line for EtherNet/IP In-Cabinet Resource-Constrained Bus System

EtherNet/IP for in-cabinet resource-constrained devices will enable the benefits of additional diagnostics, asset information and parameterization capability, automatic node topology discovery, and plug and play device replacement compared to existing hard-wired devices. Single Pair Ethernet will enable the use of one seamless CIP network for both constrained and non-constrained devices. UDP-only EtherNet/IP communication and shared in-cabinet external power and communication cabling were designed to help increase installation return on investment.

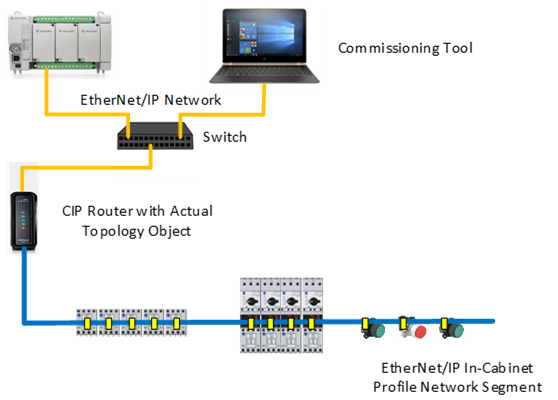

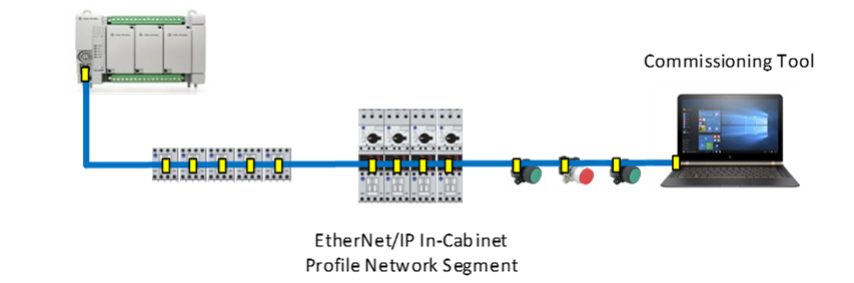

EtherNet/IP In-Cabinet Profile Network Segment with Actual Topology Object in Controller (Commissioning Tool can also host Actual Topology Object)

Expanding the connectivity of EtherNet/IP to include devices with the smallest physical footprint and most limited hardware resources opens up tremendous opportunity for further digital transformation within automation at the edge. The ability to obtain diagnostic, prognostic, and asset identity information remotely from more devices will drive down incidents of unplanned downtime and improve the efficiency of existing assets. The connection of resource-constrained devices to EtherNet/IP increases the value of existing networks for end users and reduces the need for secondary lower-level networks.

EtherNet/IP In-Cabinet Profile Network Segment with Actual Topology Object in Router

Click here to learn more about Single Pair Ethernet in the process industries via Ethernet-APL.